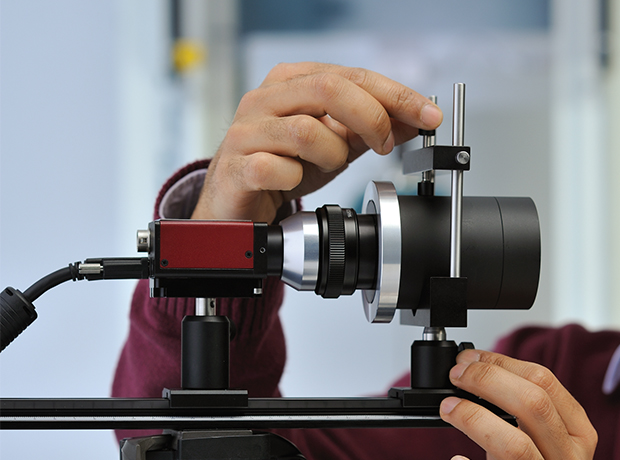

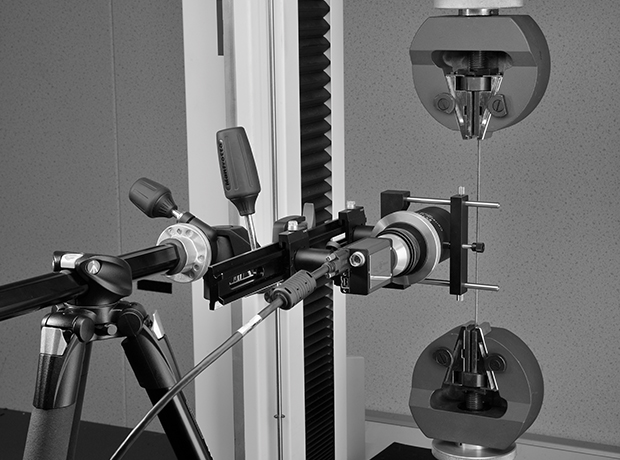

This versatile extensometer platform delivers zero gage length error every time and quick application of gage marks, including for the measurement of rotation to track specimen alignment during the test. Calibration is digitally embedded and can be verified at any time using a standard traceable gage block supplied.

Tinius Olsen’s VEM Video extensometer is straightforward to use, whether it is for a research application or as an educational tool. Test reporting is strengthened by the strain embedded video record which, along with the strain mapping option, gives depth to material analysis and reports.

VI

VI