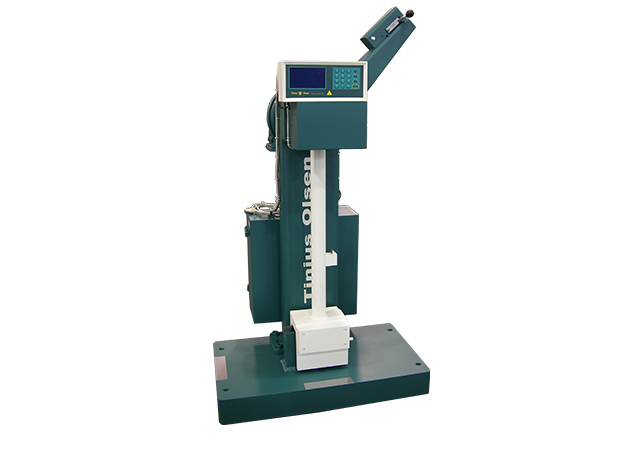

– Description:

Tinius Olsen’s popular model IT406 is a pendulum impact tester that can be easily changed from a Charpy configuration to an Izod configuration. These testers are designed primarily for determining the impact resistance of metals and are designed to fully comply with the specifications outlined in ASTM E23, EN ISO 148-3 and EN ISO 148-2.

The model IT406 provides maximum testing versatility. Easy insertion of interchangeable strikers in the pendulum head quickly adapts the machine for either Charpy or Izod testing. Two studs on the rear of the pendulum head allow optional tooling to be attached for performing tension impact tests.

A latch with a safety lock holds the pendulum in its raised position and assures a vibration-free release when activated. Once released, the pendulum quickly reaches the impact velocity of 5.47m/s (17.0ft/s) and has a maximum available energy of 406J (300ft.lbf) to impact the specimen.

The superior design and construction of the model IT406 ensures maximum testing accuracy and repeatability. When the machine is properly installed and leveled, the total frictional and windage losses during the pendulum swing are guaranteed not to exceed 0.5% of the energy range.

– Features:

- Low blow fixture allows Charpy, Izod or tension impact tests to be performed at any of 55 velocity/energy levels from the maximum of 5.47m/s (17.9ft/s) down to 0.13m/s (0.4ft/s)

- Precision, friction compensated, robust test frames

- Digital display option allows test set-up and result display

- Digital display option allows simple connection to PC for full test SPC analysis

- Safety features ensure repetitive secure testing

– Acessorries:

- Simple electric brake to slow the swinging pendulum to a stop

- Automatic motorized return eliminates the need for any operator involvement other than releasing the pendulum. The digital display is included in this option and provides the trigger to energize the motor, which catches the swinging pendulum at the optimal position and returns it to the latched starting point

- For high traffic areas, Tinius Olsen can supply a complete enclosure for the machine so that the swinging pendulum and broken specimens do not pose any safety concerns. The enclosure is completely interlocked so that the machine cannot operate unless all the guards are in place

VI

VI